You need a machine that does many jobs at once. The ksci-eyc-a series ci flexo printing embossing and edge inserting all-in-one machine lets you do this. You can print, emboss, and insert edges with just this machine. This machine is special because it does all these things together. You save time and space when you use it. The ksci-eyc-a series ci flexo printing embossing and edge inserting all-in-one machine helps you with flexible packaging needs. If you pick this machine, your work gets easier and your products get better.

Key Takeaways-

The KSCI-EYC-A Series machine does printing, embossing, and edge inserting. It helps you save time and space when you pack things.

-

CI flexo printing makes pictures look clear and colors look bright. This helps your packaging look better and makes less waste.

-

The machine has automatic systems that let you change jobs fast. This is good for custom orders and small batches.

-

Using this all-in-one machine costs less because you do not need many machines. It also helps you use less material and make less waste.

-

The machine is easy to use and you do not need special training. You can start making great packaging right away.

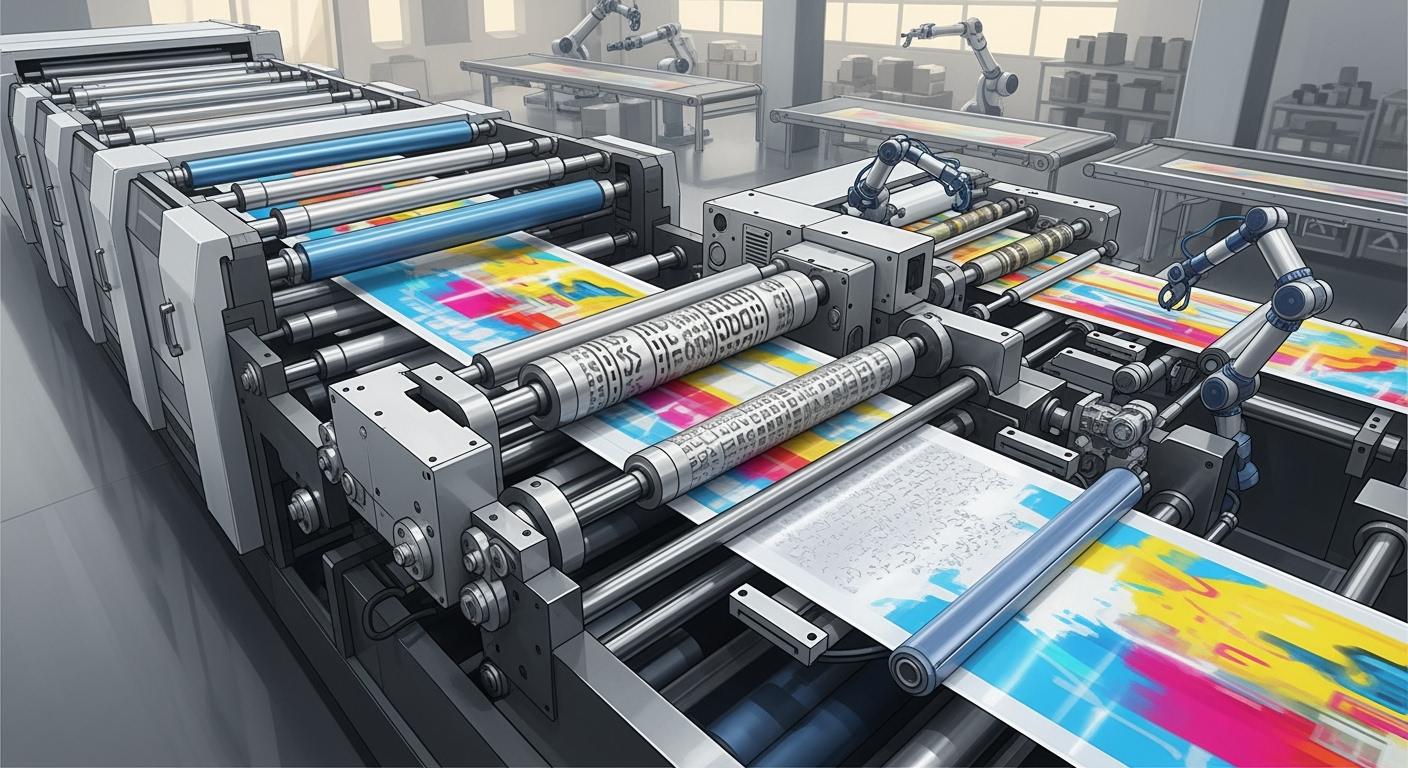

The KSCI-EYC-A Series machine helps with flexible packaging. It lets you do many steps in one place. This system combines ci flexo printing, embossing, and edge inserting. You do not have to move your materials to other machines. This saves you time and keeps your space neat. You can finish your packaging faster and get better results.

Integrated CI Flexo Printing

You can use ci flexo printing easily with this machine. A central impression drum holds your material steady. The ci drum keeps the film or substrate in place. Flexo plates put ink on the material. You get clear images and bright colors every time. The ci flexo printing system works very fast. You can print lots of material quickly. There is less waste because the process is very exact. You do not need to worry about colors moving or images getting blurry. The ci flexo printing technology keeps your designs sharp and your colors bright.

Embossing and Edge Inserting Functions

You can make your packaging stronger with embossing. The machine presses patterns into the material as it moves. You do not have to stop or use another machine. The edge inserting function adds strips or reinforcements to the sides. You can do this right after printing and embossing. This makes your packaging tougher and more useful. You finish all these steps at once.

When you use ci flexo printing, embossing, and edge inserting together, you get many good things. Here are some of the benefits in the table below:

|

Benefit |

Description |

|---|---|

|

Enhanced Flexibility |

You can use the machine for many types of packaging and materials. |

|

Reduced Production Time |

You finish your products in one pass, so you save time and reduce waste. |

|

Improved Print Quality |

The ci flexo printing system gives you sharp images and bright colors. |

|

Faster Setup and Reduced Waste |

You can switch jobs quickly and use less material during setup. |

|

Ideal for Short to Medium Runs |

You can handle custom orders and smaller batches with ease. |

You can see how ci flexo printing, embossing, and edge inserting work together. This machine does more jobs in less time. You also get better quality and more choices for your packaging.

Key Features and TechnologyWhen you use the KSCI-EYC-A Series machine, you get advanced technology that makes your work easier and your results better. This machine uses special parts and systems to give you high-quality printing and fast job changes. Let’s look at the main features that help you get the best from your ci flexo printing process.

Ceramic Anilox Roller and Doctor Blade

The ceramic anilox roller is a key part of the ci flexo printing system. It controls how much ink goes onto your material. You can choose different rollers for different jobs. The roller has tiny cells that hold the inks. The doctor blade wipes off extra inks, so only the right amount stays on the roller. This gives you enhanced print quality every time.

Here are the main specifications of the ceramic anilox roller:

|

Specification |

Value |

|---|---|

|

Screen Count Range |

30-1500 LPI |

|

Maximum Length |

100~5250 mm |

|

Diameter Range |

20 ~ 600 mm |

|

Screen Angle |

1 ~ 89 degree |

|

Cell Shape |

hexagon, quadrangle, line, etc. |

You can see that the roller fits many types of ci flexo printing jobs. The roller and doctor blade work together to keep your inks even and your printing sharp. You get bright colors and clear images on every run. This helps you keep your quality high and your waste low.

Automatic Ink System and Color Registration

You do not have to worry about mixing inks by hand. The automatic ink system does this for you. It uses computer control to manage your inks and keep them at the right level. You can store settings for different jobs, so you switch between ci flexo printing tasks quickly. The system lets you use bigger ink containers, which saves you money and time.

Here are some ways the automatic ink system helps you:

-

You use less labor because the system handles the inks for you.

-

You get fewer mistakes, so your ci flexo printing stays accurate.

-

You can change to new products or designs fast.

-

You waste less ink and material, which saves you money.

-

You get more choices for your labels and packaging.

The color registration system keeps your colors in the right place. You do not have to worry about colors moving or mixing. This gives you enhanced print quality and makes your ci flexo printing look professional. You can trust the machine to keep your designs sharp and your colors bright.

Pressure Regulation and Sleeve Technology

You need the right pressure for good ci flexo printing. The pressure regulation system lets you set the best pressure for each job. You can adjust it easily, so you get the same quality every time. This helps you avoid mistakes and keeps your printing smooth.

Sleeve technology makes job changes fast. You can switch sleeves for different ci flexo printing plates or rollers. You do not need to stop the machine for long. This saves you time and lets you handle more jobs in one day. The FDS door system also helps you change parts quickly and safely.

When you use these features together, you get many benefits:

-

You finish jobs faster with less downtime.

-

You keep your ci flexo printing quality high.

-

You use less ink and material, which saves you money.

-

You can handle many types of packaging and designs.

Tip: If you want to get the best results from your ci flexo printing, use the right inks and settings for each job. The KSCI-EYC-A Series machine helps you do this with its smart systems.

The KSCI-EYC-A Series ci flexo printing embossing and edge inserting all-in-one machine gives you the tools you need for high-quality printing. You get clear images, bright colors, and strong packaging. You can trust the flexographic printing system to help you meet your goals and keep your customers happy.

Applications in Flexible Packaging

You can use the KSCI-EYC-A Series machine for many types of packaging. This machine works best for flexible packaging. You will see it in industries that need strong, safe, and colorful packaging. Many companies use this machine to make products that protect goods and look good on store shelves.

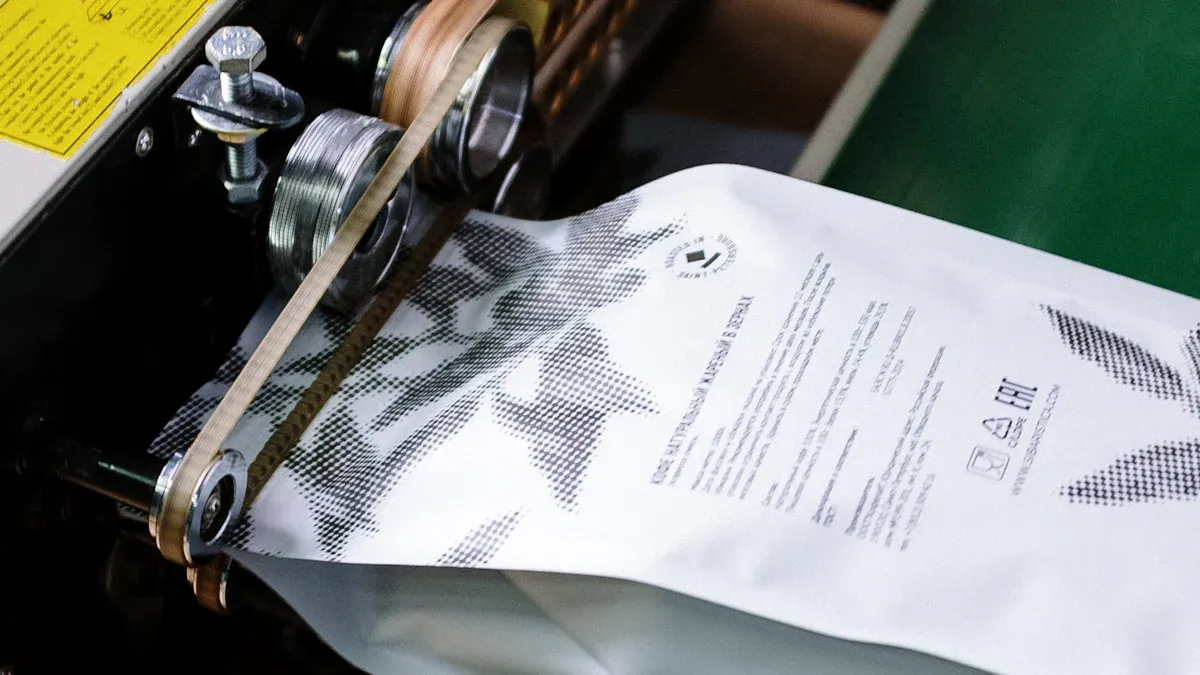

FFS Heavy-duty Film

You can make FFS heavy-duty film with this ci machine. FFS stands for Form-Fill-Seal. You use this type of packaging for products that need extra strength. You will find FFS heavy-duty film in industries like chemicals, food, and building materials. This ci machine prints, embosses, and inserts edges on the film in one step. You get strong packaging that keeps products safe during shipping. The ci system gives you bright colors and sharp images on every package. You can change designs quickly if you need to. This helps you meet customer needs fast.

Note: FFS heavy-duty film is perfect for flexible packaging because it can handle heavy loads and rough handling.

Woven Bags and Valve Bags

You can also use this ci machine for woven bags and valve bags. These bags are common in agriculture, animal feed, and construction. Woven bags need strong seams and clear printing. Valve bags help you fill products quickly and seal them tight. The ci printing system lets you add bright logos and important information to each bag. You can emboss patterns for extra grip or style. Edge inserting makes the bags even stronger. You finish all steps in one pass, so you save time and keep your packaging line moving.

Here are some typical products you can make with this ci machine:

|

Product Type |

Industry |

Packaging Benefit |

|---|---|---|

|

FFS Heavy-duty Film |

Chemicals, Food |

Strong, safe, flexible |

|

Woven Bags |

Agriculture, Feed |

Durable, easy to print |

|

Valve Bags |

Construction, Food |

Fast filling, tight sealing |

You can see that the ci machine fits many flexible packaging needs. You get high-quality packaging for many products. This helps your business grow and keeps your customers happy.

Benefits of CI Flexo Printing MachinesEfficiency and Productivity

You want your packaging line to be fast. CI flexo printing machines help you do this. The KSCI-EYC-A Series prints, embosses, and inserts edges in one step. You do not need to move materials to other machines. This saves you time and keeps your workspace neat. High-speed printing lets you finish more jobs each day. Inline flexo printing machines let you switch jobs quickly. You can handle short runs and custom orders without waiting long. Using ci flexo printing machines helps you work faster and keeps your customers happy.

Quality and Consistency

You want every package to look good. CI flexo printing machines give you sharp images and bright colors. The ci drum holds your material steady while printing. This keeps your designs clear and colors in the right spot. The flexo system uses special rollers and blades to control ink. You get the same quality on every package. Inline flexo printing machines help you avoid mistakes. You do not need to worry about colors moving or images getting blurry. Your customers will see the difference in your packaging.

Tip: Use ci flexo printing machines to keep your print quality high, even for big orders.

Cost and Space Savings

You want to save money and use your space well. CI flexo printing machines do many steps in one machine. You do not need to buy extra machines for printing, embossing, or edge inserting. This saves you money on equipment and repairs. Inline flexo printing machines use less ink and material. You waste less during setup and job changes. High-speed printing means you use less energy for each package. You also free up space in your factory for other work. The benefits of ci flexo printing machines help you spend less and grow your business.

|

Benefit |

How It Helps You |

|---|---|

|

Faster Production |

Finish more jobs in less time |

|

Better Print Quality |

Impress customers with sharp images |

|

Lower Costs |

Save on equipment and materials |

|

More Space |

Use your factory more efficiently |

When you pick ci flexo printing machines, you get more than speed. You get quality, savings, and a better way to run your packaging line.

You get lots of good things with the KSCI-EYC-A Series machine. You can print, emboss, and add edges all at once. This machine is great for flexible packaging jobs. It helps you finish work faster. You can skip problems that happen when machines do not work together. You do this by planning your workspace and teaching your team. Look at the table below to see some common problems and how to fix them:

|

Challenge |

Solution |

|---|---|

|

Layout bottlenecks |

Redesign with Lean principles |

|

Old system issues |

Integrate control systems |

|

Start-up delays |

Use staggered validations |

You make your work better and your products stronger.

FAQHow does the KSCI-EYC-A Series machine help you save time?

You can print, emboss, and insert edges all at once. You do not need to move things to other machines. This helps you finish jobs faster. Your workspace stays neat and tidy.

What types of packaging can you produce with this machine?

You can make FFS heavy-duty film, woven bags, and valve bags. These are good for chemicals, food, farming, and building work. The machine helps with many flexible packaging needs.

Can you switch jobs quickly on this machine?

Yes, you can change sleeves and settings very fast. The automatic systems help you switch designs or products quickly. You keep your line moving and handle custom orders easily.

What makes CI flexo printing different from other printing methods?

CI flexo printing uses a central impression drum to hold things steady. You get sharp images and bright colors every time. The process makes less waste and keeps your print quality high.

Do you need special training to operate the KSCI-EYC-A Series machine?

You do not need special training. The machine has automatic controls and is easy to use. You can learn the basics fast and start making good packaging with confidence.