A three layer film blowing machine makes plastic films with three layers. This machine mixes different materials into one film. The film becomes stronger and more flexible. These films are used in packaging, on farms, and in factories. The machine helps make films that protect things better. The films also last longer.

Key Takeaways-

A three layer film blowing machine makes plastic films strong and flexible. It does this by mixing three layers. Each layer has its own special features.

-

Co-extrusion lets you design films with special traits. You can pick different materials for each layer. This can give the film UV protection or better sealing.

-

You can choose ABA or ABC layer setups. ABA costs less. ABC lets you customize more.

-

Using recycled materials in the film can save money. It also helps the environment. This makes your products better for people who care about nature.

-

This machine can make films for many uses. It is good for food packaging, farming, and building. It helps businesses meet many needs.

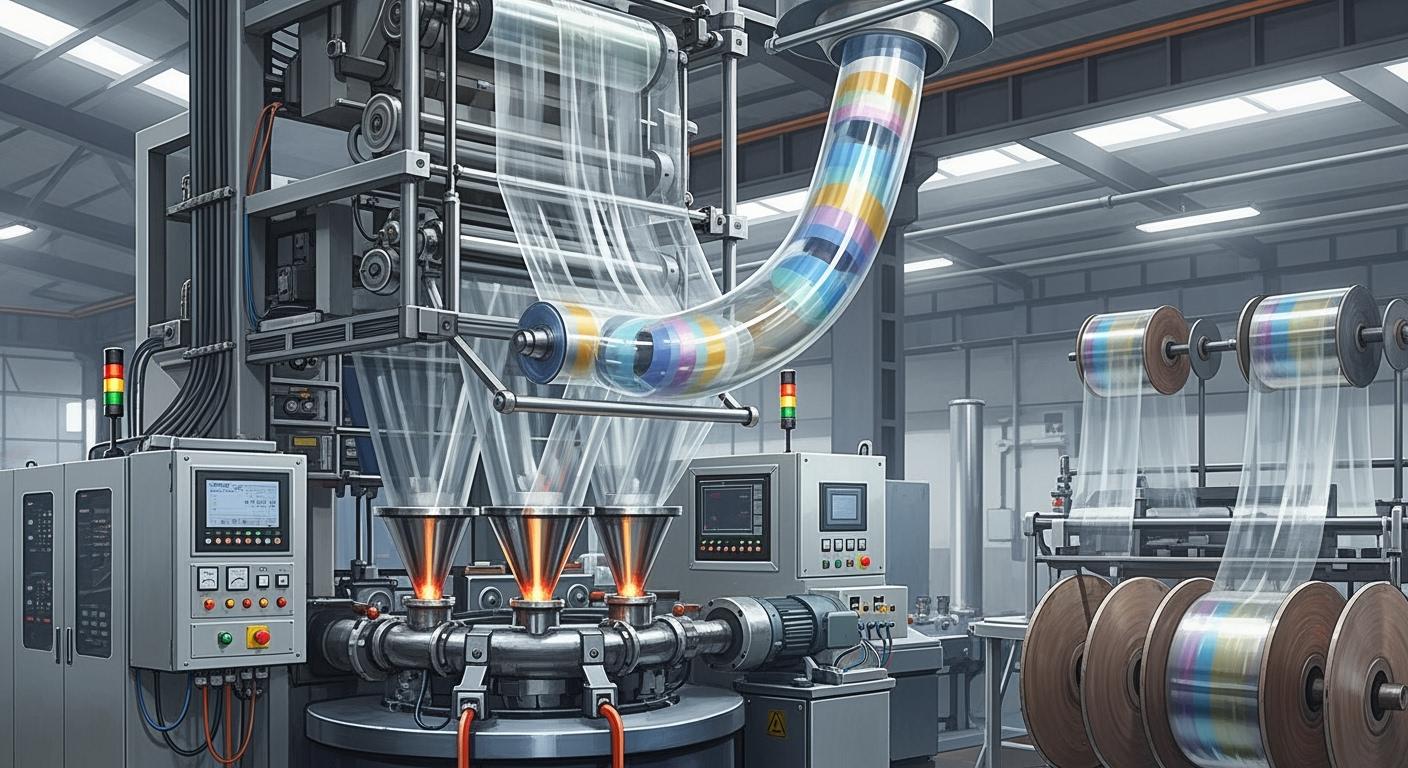

Definition and Main Function

You use a three layer film blowing machine to make strong and flexible films. This machine lets you combine three different layers into one film. Each layer can have its own material or color. You can choose what each layer does. For example, one layer can block sunlight, another can add strength, and the last can make the film seal better. When you use this machine, you get plastic films that work better than single-layer films. You can use these films for packaging, farming, or even building projects. The main function of a three layer film blowing machine is to help you create films with special features for your needs.

Tip: If you want to save money, you can use recycled materials in one or more layers. This helps the environment and lowers your costs.

Key Components and Structure

A three layer film blowing machine has several important parts. You will find three separate extruders. Each extruder melts and pushes out a different type of plastic. The melted plastics move into a special die head. This die head shapes the three layers into a single tube of film. After that, the film goes through a cooling system. The cooling system makes the film hard and smooth. Rollers then pull the film upwards and flatten it. At the end, you can cut or roll the film as you need.

Here is a simple table to show the main parts:

|

Component |

What It Does |

|---|---|

|

Extruders |

Melt and push out plastic |

|

Die Head |

Combines layers into one film |

|

Cooling System |

Hardens and smooths the film |

|

Rollers |

Pull and flatten the film |

|

Winder |

Rolls up the finished film |

When you use a blown film machine with three layers, you get more control over the film’s quality and features. This makes your products stronger and more useful.

How the Three Layer Film Blowing Machine Works

Extrusion and Co-Extrusion Process

You start the process by feeding raw plastic pellets into three separate extruders. Each extruder heats and melts the plastic. The melted plastic moves forward under pressure. You control the temperature and speed for each extruder. This step is important because it affects the quality of the film.

Next, you use co-extrusion to combine the melted plastics. The three layer film blowing machine uses a special die head for this. The die head brings the three streams together. Co-extrusion allows you to create a single film with three different layers. Each layer can have its own material or color. You can add recycled plastic or special additives to any layer. Co-extrusion gives you the power to design films with many features.

The co-extrusion process continues as the combined melt exits the die head. The film forms a thin tube. You inflate the tube with air. This step is called "blowing." The air stretches the film and makes it thin and even. Co-extrusion ensures that each layer stays in place during this step. You cool the film quickly to lock in the properties of each layer.

Note: Co-extrusion helps you save costs by using less expensive materials in the inner layers while keeping strong or special materials on the outside.

Layer Formation (ABA and ABC)

You can choose how to arrange the layers in your film. The two most common types are ABA and ABC. In an ABA structure, the outer and inner layers use the same material. The middle layer uses a different material. This setup works well when you want to use recycled plastic in the center. You keep the outside layers strong and clean.

In an ABC structure, each layer uses a different material. This gives you more options. You can make the outside layer tough, the middle layer flexible, and the inside layer easy to seal. Co-extrusion lets you control the thickness of each layer. You can adjust the settings on the three layer film blowing machine to get the exact film you want.

Here is a simple table to show the difference:

|

Structure |

Layer A |

Layer B |

Layer C |

|---|---|---|---|

|

ABA |

Same |

Different |

Same |

|

ABC |

Different |

Different |

Different |

Co-extrusion makes it easy to switch between ABA and ABC. You only need to change the materials in the extruders.

Flexibility and Material Options

You have many choices when you use co-extrusion. You can pick from different types of plastic, such as LDPE, LLDPE, or HDPE. You can add color to any layer. You can also mix in additives like UV blockers, slip agents, or calcium carbonate. Co-extrusion lets you use recycled materials in the middle layer without affecting the look or strength of the outside layers.

You can make plastic films for many uses. For example, you can make films that block sunlight for greenhouses. You can make strong films for packaging food. You can even make films that are easy to print on. Co-extrusion gives you the power to meet many needs with one machine.

Tip: Co-extrusion helps you create custom films for special jobs. You can change the recipe for each layer to match your needs.

When you use a three layer film blowing machine, you get the benefits of co-extrusion. You can make films that are strong, flexible, and cost-effective. You can also help the environment by using recycled materials. Co-extrusion gives you control over every part of the film. You can make better products for your customers.

Types and ConfigurationsABA vs. ABC Arrangements

You can pick ABA or ABC layer setups with a three layer film blowing machine. Each choice has its own good points.

-

ABA Arrangement:

In ABA, the outside and inside layers use the same material. The middle layer uses something different. ABA is good for saving money. You can put recycled plastic in the middle. The outside layers use new, clean plastic. This keeps the film strong and safe for food or other things. -

ABC Arrangement:

In ABC, every layer uses a different material. You get more control over what the film can do. The outside layer can be tough. The middle layer can be flexible. The inside layer can seal easily. ABC is best when you want special features in each layer.

Here is a simple table to compare:

|

Arrangement |

Outer Layer |

Middle Layer |

Inner Layer |

Common Use |

|---|---|---|---|---|

|

ABA |

A |

B |

A |

Saves money, recycled core |

|

ABC |

A |

B |

C |

Custom features, special films |

Tip: Pick ABA if you want to save money. Pick ABC if you want more control over the film.

Comparison with Single-Layer Machines

A three layer film blowing machine gives you more choices than a single-layer machine. A single-layer machine uses only one kind of plastic. This means the film is not as strong and has fewer features. You cannot add special layers for sealing or strength.

With a three layer machine, you can mix different materials in one film. You can use recycled plastic in the middle. You can add colors or other things to any layer. You can make films that last longer and work better.

You get more flexibility and better quality. You can save money by using cheaper materials inside the film. Three layer machines help you meet more needs and make your business better.

Advantages and ApplicationsBenefits for Manufacturers

You get many good things from a three layer film blowing machine. This machine helps you make better products. The films you make are strong and flexible. They last longer than regular films. You can change each layer to add special things. For example, you can add UV protection or make the film seal easily. The machine works fast and makes lots of film. You save time and throw away less plastic.

You can put recycled plastic in the middle layer. This saves you money and helps the planet. The outside layers stay clean and strong. Your film is safe for food and other uses. You can pick different colors and add extras. This helps you give customers what they want with one machine.

Tip: If you use recycled plastic, you can meet green rules. This can help you get more customers.

Common Products and Uses

You can make many kinds of plastic films with this machine. These films are used in lots of places. Here are some examples:

-

Greenhouse sheets for farms

-

Films for crops

-

Sheets for building sites

-

Food packaging films

-

Shopping bags and garbage bags

These films help people in real life. Greenhouse sheets block bad sunlight and protect plants. Food packaging films keep food fresh and safe. Construction sheets keep building stuff dry and clean.

|

Product Type |

Main Use |

|---|---|

|

Greenhouse Sheets |

Protect plants on farms |

|

Agricultural Films |

Cover soil and crops |

|

Construction Sheets |

Keep building materials safe |

|

Food Packaging |

Keep food fresh and clean |

|

Shopping/Garbage Bags |

Carry or hold things |

You can make many products with one machine. This helps your business grow and change easily.

You now know that a three layer film blowing machine helps you make strong, flexible films. You control each layer to match your needs. You can use different materials, colors, or recycled plastics. These machines work fast and give you many options for packaging, farming, or building.

FAQIf you want better film quality and more choices, a three layer film blowing machine is a smart investment for your business.

What materials can you use in a three layer film blowing machine?

You can use LDPE, LLDPE, HDPE, or blends. You may also add color, UV blockers, or recycled plastic. Each layer can have a different material to match your needs.

How do you switch between ABA and ABC structures?

You only need to change the materials in each extruder. The machine setup stays the same. You can quickly adjust recipes for different film types.

Can you use recycled plastic in these machines?

Yes! You can put recycled plastic in the middle layer. This helps you save money and protect the environment. The outer layers stay clean and strong.

What maintenance does a three layer film blowing machine need?

-

Clean the die head and extruders often.

-

Check the cooling system.

-

Lubricate moving parts.

-

Inspect rollers and winders.

Regular care keeps your machine running well and your films high quality.