You can create paper bags quickly and easily with a Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing Online. This machine works with materials like Kraft paper and coated paper. You control everything using a touch screen. The sharp bottom design makes each bag strong and neat. The built-in color printing lets you add bright designs or logos as the bags are made. You get fast results with less effort, making the Full Automatic High Speed Sharp Bottom Paper bag a smart choice for many businesses.

Key Takeaways-

The Full Automatic High Speed Sharp Bottom Paper Bag machine makes strong bags fast. The bags look neat and clean. This helps businesses save time and work.

-

This machine has a touch screen that is easy to use. You can change the bag size and printing choices with it.

-

You can print bright designs or logos right on the bags. You can use two or four colors. This helps people notice your brand more.

-

The sharp bottom design makes the bags stronger. This is good for food packaging and stores.

-

Automation in the process lowers mistakes and boosts how many bags are made. This lets the machine work very fast.

You get many advantages when you use a Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing Online. This machine combines automation, speed, strong bag design, and colorful printing. You can work with different paper types and sizes. You control everything with a touch screen, making the process simple and efficient.

Full Automatic Operation

You do not need to handle each step by hand. The machine takes care of the whole process for you. Here are the main automation features:

|

Automation Feature |

Description |

|---|---|

|

Roll Feeding |

Automatically feeds paper roll into the machine. |

|

Side Gluing |

Applies glue to the sides of the paper. |

|

Tube Forming |

Forms the paper into a tube shape. |

|

Tube Cutting-off |

Cuts the formed tube to the desired length. |

|

Bottom Folding and Gluing |

Folds and glues the bottom of the bag. |

|

Bag Collection |

Collects the finished bags automatically. |

You can rely on these features to save time and reduce mistakes. The touch screen interface lets you set up the machine quickly. You can adjust settings with just a few taps.

High Speed Output

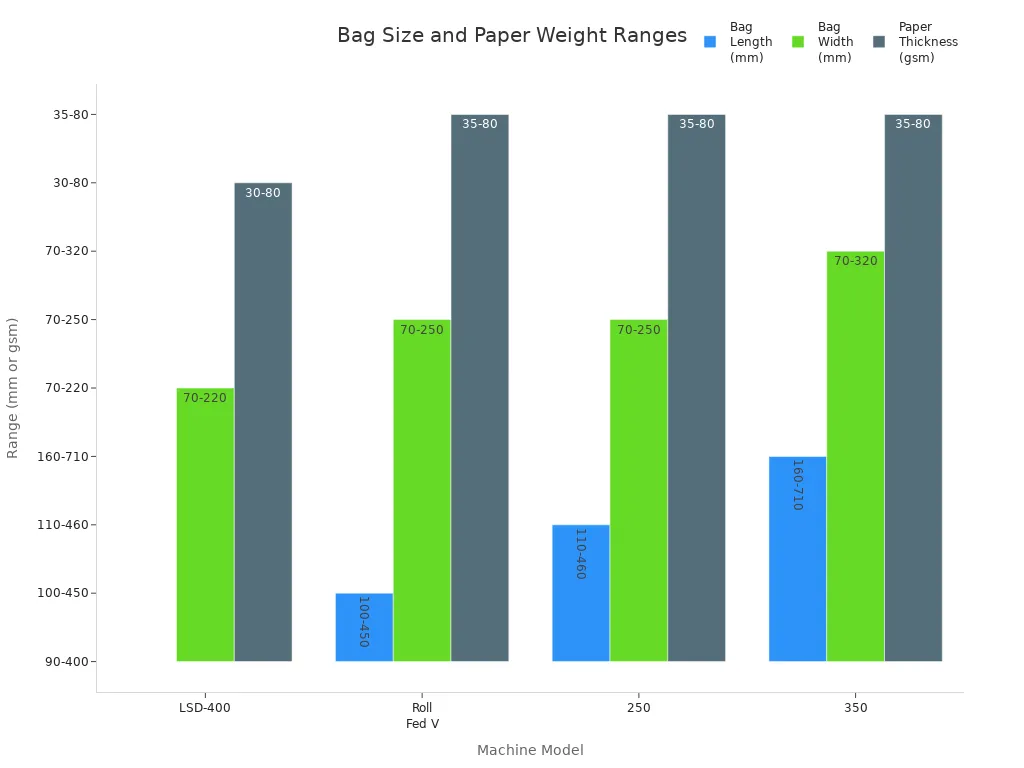

You can produce bags at a very fast rate. Some models reach speeds up to 610 pieces per minute. You can choose the right model for your needs. The chart below shows the range of bag sizes and paper thickness for different machines:

You can see that each model covers different bag lengths, widths, and paper thicknesses. Here is a table for quick reference:

|

Model |

Bag Length (mm) |

Bag Width (mm) |

Paper Thickness (gsm) |

|---|---|---|---|

|

LSD-400 |

90-400 |

70-220 |

30-80 |

|

Roll Fed V |

100-450 |

70-250 |

35-80 |

|

250 |

110-460 |

70-250 |

35-80 |

|

350 |

160-710 |

70-320 |

35-80 |

You can select the right settings for your bag size and paper type. The machine works with Kraft paper and slick paper. You can also use eco-friendly paper and block bottom or flat & satchel bag styles.

-

Kraft Paper Bag Making Machine

-

Eco-friendly Paper Bags Equipment

-

Block bottom bag making machine

-

Flat & satchel paper bag making machine

Sharp Bottom Design

You get bags with a sharp bottom that look neat and hold their shape well. This design helps you make bags quickly and in large numbers. You can use these bags for food packaging because they are strong and easy to fill. The sharp bottom design improves production efficiency and keeps each bag sturdy.

Tip: If you need bags for food or retail, the sharp bottom design gives you extra strength and a clean look.

2/4 Color Printing

You can print bright designs or logos directly onto each bag as it is made. The Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing Online lets you choose between two or four colors. You get better brand visibility and more options for your designs. Here are the benefits and limitations:

|

Benefits |

Limitations |

|---|---|

|

Enhanced visual appeal |

Higher cost compared to single color |

|

Versatility in material compatibility |

Complexity in design |

|

Better brand visibility |

|

You can use color printing to make your bags stand out. You can attract more customers with eye-catching designs. You can also print important information on each bag.

Summary Table: Key Specs|

Feature |

Details |

|---|---|

|

Max Speed |

150m/min |

|

Paper roll width |

380-1350mm |

|

Bag Width |

120-450mm |

You can see that the Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing Online covers a wide range of needs. You get speed, automation, strong bags, and colorful printing all in one machine.

How It Works

When you use a Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing Online, you get a smooth, step-by-step process from start to finish. Each stage uses advanced automation to make your work easier and faster.

Paper Feeding

You start by loading large rolls of paper onto the machine. Pneumatic cylinder lifting systems help you lift and place the heavy rolls with little effort. The machine unwinds the paper and uses constant tension control systems to keep the paper flat and smooth. This prevents wrinkles and keeps the paper aligned. You do not need to adjust the paper by hand because the sensors and controls handle it for you.

Printing Process

Next, the machine prints your designs or logos directly onto the paper. Flexographic printing units add up to four colors as the paper moves through the system. You can choose two or four colors for your bags. The printing happens in real time, so you see your designs appear instantly. The machine uses precision rollers and ink controls to make sure each print looks sharp and bright.

Tip: You can change your design or logo easily using the touch screen controls.

Bag Formation

After printing, the machine folds and cuts the paper into the right shape. Advanced folding plates and servo-controlled systems shape the paper into a tube. High-precision rotary cutters slice the tube into bag-sized pieces. The machine then folds and glues the bottom, creating the sharp bottom design. Water-based adhesives and hot-melt glue systems make sure each bag is strong and secure. Optical sensors check for any mistakes during folding and gluing.

Output and Collection

Once the bags are formed, the machine collects them in neat stacks. Automated cameras inspect each bag to make sure it meets quality standards. If you need handles, the machine can attach them automatically. Finally, the finished bags are ready for packaging and shipping. You get a steady flow of sharp bottom paper bags, all printed and stacked, with very little manual work.

AdvantagesNote: Automation at every stage helps you save time, reduce errors, and keep your production line running smoothly.

Efficiency

You can get more work done with this machine. It works fast and does many jobs at once. You do not have to do much by hand. Here are some ways it helps you work better:

-

You make more bags in less time because it is fast.

-

The machine does most of the work, so you pay less for workers.

-

Many parts work together to make your job easier.

You can see these good things happen:

-

The machine can make lots of bags for big orders.

-

You do not need to do as much work yourself.

-

It uses less energy, so you save money on power.

Using this machine helps you fill big orders and keep your business working well.

Print Quality

You can make bags with bright and clear prints. The printing system lets you put logos or designs right on each bag. Every bag has sharp pictures and strong colors. The machine uses flexographic printing, so you get great results quickly. Your bags look nice and help people notice your brand.

Versatility

You can use this machine for many kinds of bags and papers. It works with different sizes and materials. You can make bags for food, stores, or special needs. The table below shows some features:

|

Specification |

Details |

|---|---|

|

Product Type |

Paper Bag Making Machine |

|

Processing Type |

Paper Folding Machine |

|

Production Capacity |

400 |

|

Voltage |

220V/380V |

|

Power (w) |

15KW |

|

Dimensions (lwh) |

295013201500mm |

|

Application |

Paper Bag Production |

|

After-sales Service Provided |

Engineers available to service machinery overseas |

|

Customization |

Available |

You can change bag sizes and paper types easily. This helps you make bags for many customers.

User-Friendly Controls

You can use the machine even if you are new. The touch screen shows you what is happening right now. You can change bag size, folding, and glue with a few taps. The table below lists some easy-to-use features:

|

Feature |

Description |

|---|---|

|

User-friendly adjustment |

Change bag size, folding, handle, and glue easily |

|

Automatic systems |

Help you work faster and do less by hand |

|

Intuitive interfaces |

Make using and fixing the machine simple |

|

Touch screen interface |

Shows you what the machine is doing |

|

Motion Control System |

Keeps the machine working smoothly |

|

Automatic counting |

Lets you set how many bags to make, so you can track them |

ApplicationsYou can learn the controls fast and keep your work going with less trouble.

Retail Bags

Sharp bottom paper bags with color printing are used in many stores. These bags are good for shopping and packing things. You see them in clothing stores, bookstores, and gift shops. The strong bottom lets you carry heavy things safely. Colorful printing helps show your brand or logo. Stores pick these bags because they look nice and help people remember them.

Tip: Use bags with your logo and bright colors to stand out. People will notice and remember your store.

Here is a table that shows where these bags are used:

|

Industry |

Description |

|---|---|

|

Retail & Daily Use |

Shopping and packaging in stores |

|

Industrial & Logistics |

Transporting goods |

Food Packaging

These bags are used a lot in food service. Places like KFC and McDonald's use them for takeout food. Bakeries use them for bread and pastries. The sharp bottom keeps food safe and standing up. The machine makes many food bags quickly. You can print menus, logos, or safety tips on the bag.

|

Feature |

Description |

|---|---|

|

Machine Model |

LMD-400+LST-4700 Automatic High Speed Flexo Printing Paper Bag Making Machine |

|

Applications |

Bread bags, KFC bags, McDonald's bags, and other food packaging |

Note: Food bags must be strong and clean. This machine helps you make bags that work well for food.

Custom Printed Bags

You can make custom printed bags for many things. Businesses want special bags for events or ads. You can print in two or four colors to make bags look different. These bags are good for hygiene items, medical supplies, and eco-friendly projects. You can pick the size, paper, and design you want.

-

These bags are used for:

-

Medical supplies

-

Hygiene products

-

Agricultural goods

-

Environmental protection

-

Custom printed bags help you share your message and grow your brand. You get good quality and many choices with every order.

Choosing a MachineProduction Needs

First, think about what you want to make. If you need to make lots of bags fast, pick a high-speed machine. Fully automatic machines help you work quicker and make fewer mistakes. Machines with strong parts last longer and break less. Here is a table to help you compare:

|

Factor |

Description |

|---|---|

|

Production Efficiency |

High-speed machines can make hundreds or thousands of bags each minute. |

|

Automation Level |

Fully automatic machines work over 50% better than semi-automatic ones. |

|

Stability |

Good parts mean less downtime and more reliable work. |

Printing Requirements

You might want to put your own designs or logos on bags. Many machines let you print right on the bags. Some machines use printing presses, and others have printing units inside. You can also look for extra features:

-

UV coating and embossing add cool effects.

-

Eco-friendly ink helps you make special or green bags.

Tip: Pick a machine that fits your printing needs so your bags look great.

Speed and Automation

Speed and automation change how many bags you can make. Fast machines help you finish jobs quickly and do them right. Automated systems can work all day and night, so you do not waste time. Some machines use data to change settings as they work. This keeps your work going smoothly. Here is a table to show how automation helps:

|

Impact Area |

Description |

|---|---|

|

Increased Throughput |

Automation makes tasks faster and gives you more bags. |

|

Reduced Cycle Times |

Faster work means less waiting and quicker results. |

|

High-Quality Production |

Robots help stop mistakes and keep bags looking good. |

|

Lights-Out Manufacturing |

Machines can run without people, so you get more done. |

Budget and Support

You need to plan your money before you buy a machine. The biggest cost is the machine itself. Fully automatic machines cost more but save money later. You also need money for paper and other supplies. Try to keep maintenance costs under 5% of the machine price each year. Here is a table to show the main costs:

|

Cost Component |

Description |

|---|---|

|

Capital Investment |

The machine costs the most, but it works very well. |

|

Working Capital |

You need enough supplies to keep making bags. |

|

Maintenance Costs |

Try to spend less than 5% of the machine price each year on repairs. |

You should also check what support you get. Good support means help any time, quick answers, spare parts, and training. These things help you fix problems fast and keep your machine working.

Full Automatic High Speed Sharp Bottom Paper Bag with 2/4 Color Printing OnlineNote: Good support and training help you use your machine and fix problems quickly.

Why Pick This Machine?

You want a machine that makes work simple and fast. The full automatic high speed sharp bottom paper bag with 2/4 color printing online does this for you. It uses new technology to help your business do better. You can make more bags in less time. This machine helps you stay ahead of others.

Here are some main reasons to pick this machine: You save time because it works very fast. The bags are strong and have a sharp bottom. They look neat and keep their shape. You can print two or four colors on each bag as they are made. You use a touch screen to control everything. You can make bags for groceries, bakeries, or medical supplies.

Tip: This machine helps your business grow and makes customers happy.

What Makes This Machine Special

You might wonder why this machine is different. The table below shows what makes it special and what you get:

|

Unique Selling Points |

Description |

|---|---|

|

Advanced Technology |

You get the newest features for better work and less trouble. |

|

High Efficiency |

You make more bags quickly, so big orders are easy. |

|

Customization Options |

You can change the machine to fit your needs and bag styles. |

This machine gives you more control and better results. You do not need to worry about slow work or mistakes. The machine keeps making bags without stopping.

Best Ways to Use This Machine

You can use this machine in many places. The table below shows some good ways to use it and its features:

|

Feature |

Details |

|---|---|

|

Model |

BAGMAC Senior 2-B |

|

Production Capacity |

10,000 pieces per hour |

|

Bag Size Range |

Width: 10 cm to 45 cm, Length: 15 cm to 60 cm |

|

Application |

Grocery, Medical, Bakery Paper Bags |

|

Printing Capability |

Double color online flexo printing |

|

Automation |

Fully Automatic |

|

Material |

Iron |

|

Moisture Resistance |

Yes |

You can make bags for food, stores, or hospitals. The machine can make many bag sizes, so you can help many customers. The bags can also keep food safe from moisture.

Note: You can count on this machine to make strong, nice bags for many uses. You get speed, strength, and good printing in one machine.

If you want your business to do better, this machine is a smart pick. You get new features, fast work, and you can make special bags for many jobs.

You have learned what this machine can do. It makes bags quickly and prints designs on them. The bags are strong and can be used for many things. You can control the machine easily with simple buttons. There are many choices for bag sizes and types. Here are the main good things about this machine:

|

Feature |

Details |

|---|---|

|

High Speed |

Makes up to 350 bags every minute |

|

Custom Printing |

Can print with 2 or 4 colors |

|

Versatility |

Works with many bag sizes and papers |

|

Food-Grade Capability |

Makes safe bags for food and stores |

If you know these things, you can pick the best machine. This helps you make good choices for your business.

FAQWhat types of paper can you use with this machine?

You can use Kraft paper, slick paper, and eco-friendly paper. The machine works best with paper weights from 40gsm to 80gsm. You get strong, neat bags every time.

How do you change the bag size?

You adjust the settings on the touch screen. The machine lets you pick the bag width and length. You do not need special tools. You can switch sizes quickly.

Can you print your own logo or design?

Yes! You upload your logo or design to the machine. The built-in printer adds it to each bag as it is made. You can use two or four colors for bright, clear prints.

How fast can the machine make bags?

The machine can make up to 610 bags per minute. You can choose a slower speed if you want. High speed helps you finish big orders quickly.

Is it hard to learn how to use the machine?

You do not need to worry. The touch screen shows clear instructions. You can learn the controls in a short time. Most people start making bags on the first day.