Date: 2024.10.31 Click: 71

Introduction

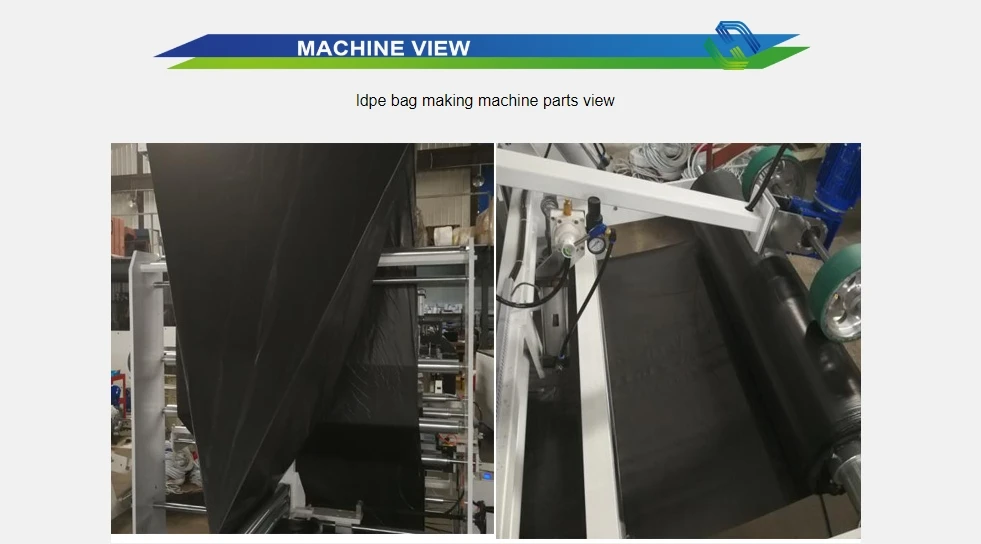

In today's packaging industry, bag-making machines are regarded as essential equipment. Their primary function is to produce various types of bags, such as plastic bags, paper bags, and composite bags, making them widely applicable across industries like food packaging, pharmaceuticals, and daily chemicals. With the diversity of packaging demands and advancements in automation technology, bag-making machines have become crucial for operational efficiency, production quality, and precision, significantly influencing product quality and a company's manufacturing capabilities. This article explores the core operation methods and main components of bag-making machines, aiming to provide a comprehensive understanding of their working principles and the functionality of each component.

The main operational process of bag-making machines can be divided into several core steps:

From the introduction of raw materials to the final processing of finished bags, these stages achieve high efficiency through automation, significantly improving overall production efficiency and product quality.

Each stage in the plastic bag production process plays an essential role:

The feeding system is an indispensable core component of a bag-making machine, ensuring stable material transfer across forming, heat-sealing, and cutting stages. It includes key components such as:

Uniformity and stability in feeding greatly influence the precision of subsequent shaping and cutting stages. Through the combined efforts of the tension controller and sensors, material shifts and wrinkles can be avoided, laying a solid foundation for forming and cutting. This precise operation enhances the quality of the final product and helps minimize material waste.

The forming device is essential in determining the bag’s external shape. Through techniques such as folding, stretching, and guiding, it constructs the basic structure of the bag, bringing it closer to its intended shape. The forming device can be adjusted according to the requirements of different bag types, ensuring that the final product meets specified standards.

The types of forming devices vary according to the shape of the bag, including:

Different forming devices cater to the diverse needs of bag production, ensuring adherence to various packaging standards and preferences.

The heat-sealing device seals the bag's opening by heating the material. Common heat-sealing methods include:

By adopting different sealing methods, the system accommodates various material types and usage requirements, ensuring tight and stable sealing of the bags.

Cutting mechanisms divide the material at specific points in the packaging to create individual bags. High-precision cutting methods ensure neat and orderly cuts, enhancing the aesthetic appeal of the product and reducing material waste. Cutting devices play a critical role in bag-making, particularly in determining the appearance of the finished bag.

The control section of a bag-making machine mainly comprises components such as the control panel, various sensors, and precision driving devices. Its functions include:

The control system’s fine adjustments during the bag-making stage can significantly reduce errors and improve bag uniformity. Throughout the operation, this control system can intelligently adjust to various production demands, including material selection, thickness adjustment, and temperature regulation. This precise control method optimizes the production process, minimizing unnecessary downtime and excessive material consumption.

When exploring the operational mechanism and process of bag-making machines, relevant equipment manuals and literature on automated processes are valuable for understanding the key operational steps and working principles.

"4mmx2mm Disc Magnet" from S****** received 4 quotation(s)