Date: 2024.10.30 Click: 386

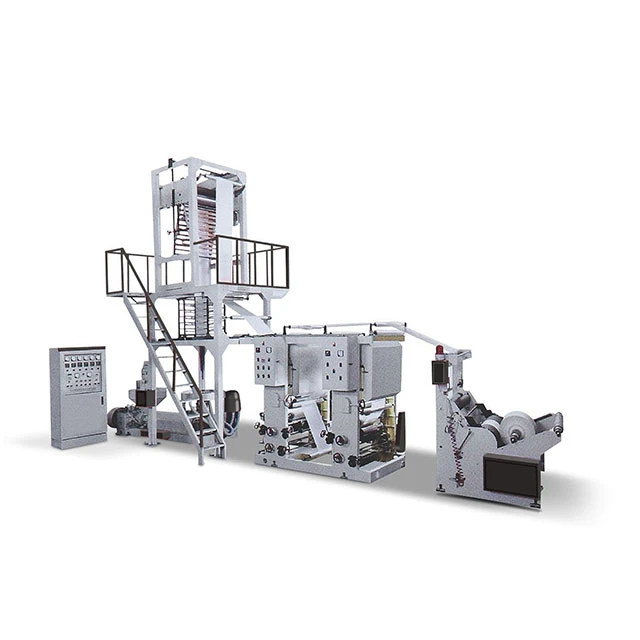

As a key instrument in the manufacturing of plastic films, blown film extrusion machines play a critical role. In modern production processes, the efficiency and stability of these machines directly determine the quality of the film products and the overall production outcomes. Safety must be prioritized when operating blown film extrusion equipment, and any negligence could lead to serious consequences. To ensure both operator and equipment stability, this study provides a detailed analysis of the essential safety considerations when operating blown film extrusion machines.

Before using a blown film machine, a thorough safety inspection of the equipment is essential. First, the equipment should be checked for any visible defects, such as cracks or damage, as these could lead to operational problems or accidents. Electrical connections, including the power supply and grounding, should also be meticulously inspected. Power cables, switches, and outlets must be in good working order and properly grounded to avoid electrical issues. Additionally, key transmission components, such as gears and belts, should be inspected for lubrication levels and wear. Insufficient lubrication or worn components may cause the machine to malfunction or produce excessive noise, potentially leading to equipment failure.

Before operating a blown film machine, operators must make comprehensive safety preparations. First, they should be equipped with personal protective equipment, such as safety helmets, goggles, and earplugs, to protect against potential hazards. This protective gear helps safeguard the head, eyes, and hearing from external injury. Next, it is essential to secure any loose clothing or accessories; long hair should be tied back, and loose items such as clothing, gloves, or necklaces should be avoided to prevent them from getting caught in the machinery. Additionally, maintaining a high level of safety awareness is crucial. It is strictly prohibited for individuals without professional training or practical experience to operate the blown film machine to avoid safety risks from improper operation.

Familiarity with the equipment’s theoretical and practical workings is crucial for operating a blown film machine. Before starting the machine, operators should carefully read the equipment’s user manual, understanding the machine’s basic structure, operation principles, and usage guidelines. At the same time, ensure that all warning labels and safety protections are functional, as these play a critical role in alerting operators and preventing hazards. When operating, keep a safe distance from major machine components to avoid injury from mechanical failure or incorrect operation.

During the operation of a blown film machine, emergencies may arise unexpectedly. Therefore, operators must be adept at emergency shutdown and power-off procedures to respond quickly to unexpected situations. Effective communication with maintenance personnel is also crucial; in the event of equipment failure or a safety incident, the operator should promptly coordinate with maintenance staff to find a solution. Additionally, in the event of fire or other emergencies, the team should implement appropriate firefighting measures and promptly report to authorities to ensure the safety of personnel and equipment.

Regular maintenance is vital to ensure the smooth operation and extended service life of blown film machines. Operators should perform periodic maintenance and repairs as guided by the equipment manual. This includes cleaning internal dust and foreign objects and inspecting electrical wiring. Routine cleaning helps maintain internal cleanliness and airflow, preventing malfunctions caused by dust or debris accumulation. Ensuring proper operation of the electrical wiring is also essential, and any abnormalities should be promptly repaired or replaced to prevent electrical hazards.

In summary, the safety considerations in blown film machine operations are essential for ensuring operator safety and stable machine operation. Operators must always maintain a high level of safety awareness and strictly follow equipment manuals and safety standards. Additionally, in-depth training and education for safety personnel are essential to enhance their awareness. By ensuring safe production practices, companies can maintain a smooth production flow and support sustainable growth.

This content is based on several primary sources: Operation and Safety Guidelines for Blown Film Machines — which provided a solid technical foundation on machine operation processes, safety protocols, and maintenance practices. Industry Experts and Experienced Operators contributed their insights, sharing real-world cases and practical experiences in addressing potential safety hazards. Safety Regulations and Standards — national and industry safety standards for plastic film production equipment were referenced to ensure that this study’s conclusions and content are legal and compliant.

It is important to note that each blown film machine model may have slight operational differences and safety guidelines. Therefore, in real-world applications, operators should follow the equipment’s user manual and safety protocols, adjusting according to specific situations. The safety recommendations provided here are for reference only and are not a substitute for professional safety training or guidance.

"4mmx2mm Disc Magnet" from S****** received 4 quotation(s)